ABOUT US

ABOUT US

The company was founded on September 28, 2000, and is located in Wuxi, the pearl of taihu Lake with beautiful scenery. Wuxi has been a land of fish and rice since ancient times. It has been known as cloth wharf, money wharf, kiln wharf, silk capital and rice market. It is a famous historical and cultural city of China. Wuxi is the cradle of China's national industry and township industry, She is the birthplace of the Southern Jiangsu model. The Company Hudai factory covers an area of 36,600 square meters, with a plant area of 34,000 square meters. It is a garden-style workshop with intelligent manufacturing and low energy consumption and environmental protection. At the beginning of its establishment, the company conducted a detailed investigation and survey on various industries in Europe, America, Japan and South Korea, which were technologically advanced and advanced at that time, and anticipated that electronic technology and electronic product manufacturing would become one of the key development directions in China in the future. Therefore, We resolutely entered into the leading electronic surface mount manufacturing industry at that time. And our target was to be the top EMS and OEM plant for the world-renowned electronic companies in China. Relying on the standard quality system and high-end manufacturing equipment, the company has established and maintained a leading position in the MANUFACTURING industry of SMT PCB and FPC FLEXIBLE circuit board. For 20 years, it has not only provided high-quality services to high-end customers such as SONY SHARP HITACHI KONICA& MINOLTA XiaoMi and Huawei, but also developed our own management and operation ability rapidly. Become the leader of SMT industry Association in Jiangsu Province. |

In 2016, the board of directors of the company decided to enter the integrated circuit and sensor industry. It has successively established the integrated circuit Packaging division and sensor packaging Division, and obtained the certification of national high-tech enterprise and national small and medium-sized science and technology enterprise.

Company was founded in 2018 advanced integrated circuit manufacturing technology research and development center, with Japanese many electronic design center and all-round cooperation domestic famous universities, photoelectric relay frame, photoelectric products involving laser tube manufacturing technology series, temperature and humidity sensor module framework, thermopile sensor using nitrogen production technology, 5G optical sensor production testing technology, mobile LCD module, PM2.5 particles sensor placement process, UVC - LED the family health care products, and other fields.

The company has three business divisions:

Established in September 2000, the Electronic Products Division is mainly engaged in SMT processing center and assembly and test processing business: including 12 Panasonic SMT production lines, Panasonic AI machine plug lines and Jingtuo wave soldering assembly and test lines. Use Matsushita error prevention system and Haobang MES system to ensure product quality and safety. And the PCBA&FPC products continue to develop innovative technology.

The IC Packaging and Testing Division was established in December 2016. It has a 1000-classes purification workshop covering 2000 square meters, and its packaging types include SOT23, QFN, SOP7-24, DIP7-24 and other packaging forms. The advantages are SIP packaging and complex multi-chip framework design capabilities, providing customers with integrated solutions from framework design to packaging, greatly improving the flexibility of customer products and greatly reducing customer costs. And can quickly complete from the design to the mass production of finished products quickly to the market, so that customers always walk ahead of competitors, keep the lead.

Founded in October 2018, the Sensor Business Unit has a hundred-class dust-free workshop covering 800 square meters. Its OEM products include temperature and humidity sensors, pressure sensors, silicon and wheat sensors, gas sensors, optical communication sensors, acceleration sensors, geomagnetic sensors and other high-end MEMS products.

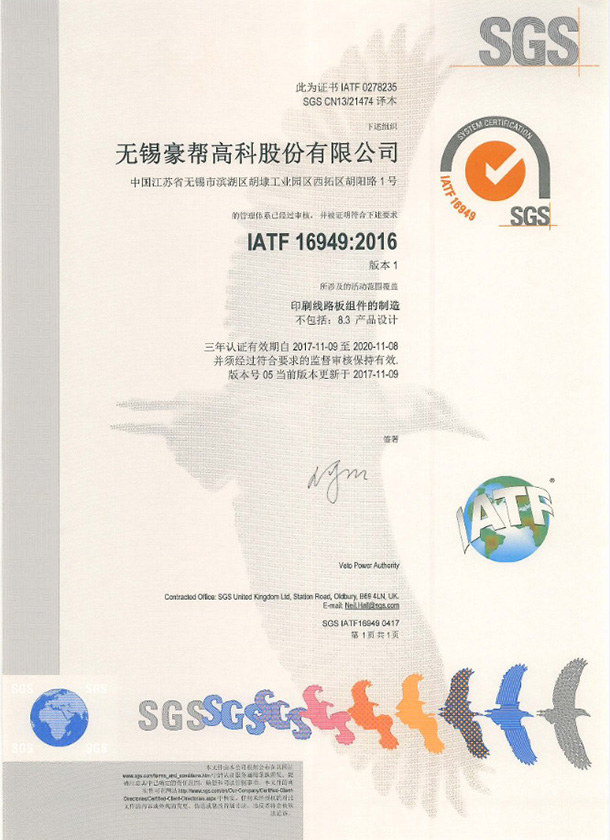

The company has obtained ISO9001, ISO14001 and IATF16949 certifications. Through the integration of China and the integration of intellectual property rights standards. Use ERP&MES to connect and improve the production and quality traceability system, the whole company is running in the encryption software platform, to provide effective protection for customers' intellectual property rights.

For a long time, the company has maintained good cooperation with customers in the fields of packaging framework, packaging technology, multi-chip packaging, SIP packaging and so on, and has obtained the naming and distribution rights of many customers' chips and sensor products. I believe that China's IC and sensor industry will have greater development space in the future. I look forward to working with you to seize the opportunity to jointly create valuable products and services for the world.

Integrated circuit division was established in December 2016. It has a thousand-level purification workshop of 2000 square meters, which can be used for SOT23, SOT89, sop7-24, dip7-24 and other packaging forms. It has IC framework design capability.

Sensor division was established in October 2018, with a 100-level dust-free workshop of 800 square meters, specializing in the production and development of temperature and humidity sensors, pressure sensors, silicon wheat sensors and other high-end products.

Established in October 2018, optoelectronic products division specializes in the production and development of laser products, optical couplings, optical relays and other products.

The four business divisions all provide corresponding application systems and solutions, and use the perfect MES system and ERP for production process management. At the same time, we has obtained some certification, such as ISO9001, ISO14001 and IATF16949 .

Quality Guarantee

Quality Guarantee

Quality Policy Insist Quality first, Implement scientific management Promote professionalism, ensure customer satisfaction | Quality Target Product DPPM≤20PPM Customer satisfaction 100% |